Are you having difficulties with thermal management in your electric vehicle (EV) ? Are you looking for a cooling solution that doesn’t add total weight? If so, a lightweight battery cooling plate might be the answer to increasing the performance and safety of your EV battery project.

Let’s delve into why these cooling plates are crucial for modern electric vehicles.

Is battery cooling really necessary for electric vehicles?

Yes, if you want your electric car to have a longer cruising range, you need a larger capacity battery pack, and EV batteries generate a lot of heat during operation. Without proper cooling, battery temperatures can exceed safe limits, leading to a 30% reduction in battery lifespan and increasing the risk of thermal runaway. Effective cooling systems, such as water cooling plates, are essential to maintain optimal performance and safety.

Excessive heat can ruin your battery performance and put you at a huge safety risk, so cooling is a big deal for your EV.

With various cooling technologies available, which one stands out in the EV industry?

Liquid cooling—water cooling plates—are the most popular because they do the best job of heat exchange. Generally, EV battery packs ranging from 50 kWh to over 100 kWh benefit greatly from liquid cooling. According to a report by the International Journal of Thermal Sciences, water cooling is 20% to 25% better than air cooling in high-capacity battery systems.

Battery pack manufacturers favor water cooling plates for their efficiency in handling high heat loads in compact spaces, making them ideal for modern EV designs.

So, how about “Lightweight Battery Cooling Plates”?

They are components made from materials like lightweight aluminum that manage battery temperatures without adding weight. For instance, XD Thermal offers battery cold plates that are 31.2% lighter than traditional designs, featuring channels for coolant circulation that stabilize battery cell temperatures.

These plates are essential for maintaining optimal battery performance while keeping the vehicle’s weight to a minimum.

This liquid cooling system cuts your overall vehicle weight, giving you up to 10% more driving range. With this lightweight battery cooling plate, you’ll not overheat your battery so it runs better, which means you can charge it about 15% faster and even it lasts 20% longer.

For example, XD Thermal’s case study demonstrated that optimizing cold plate design not only improved thermal performance but also reduced the battery pack’s weight by over 37.3%, directly impacting the vehicle’s range and efficiency.

I presume you will ask this question—”Are these lightweight cooling plates reliable over time?”

They dissipate heat great because they are made of metals with good heat properties, like aluminum alloys such as A3003, A6061. Advanced manufacturing processes like continuous brazing create high-quality liquid cooling solutions. According to our customers who have cooperated with us for many years (battery pack technical engineers), vacuum-welded cooling plates sourced from us retain their mechanical properties, are around 22% more impact-resistant, and have a 14.5% longer service life compared to traditional methods.

This means you get a reliable cooling solution that performs effectively throughout the vehicle’s life.

Absolutely. Manufacturers offer customized cooling plate designs to match specific battery pack architectures. One liquid-cooled plate doesn’t fit all battery pack solutions.

Side heat exchange or bottom heat exchange? Or is it multi-sided heat exchange? What is the capacity of the battery pack? How long does it take to achieve a cooling cycle, and what is the car’s working environment like? XD Thermal, for example, has a professional team to assist in developing tailored battery cooling solutions, reducing development cycles by up to 30% and ensuring optimal thermal management for different EV models.

I totally understand you wanting to buy a standard liquid cooling plate so you can just take it back and test it or use it, but it has to be said that for EV battery heat exchanges there is no such thing as a standard cold plate. Only customization ensures that the cooling plates meet the exact requirements of your vehicle, enhancing performance and efficiency.

Reputable manufacturers specializing in EV battery cooling solutions include XD Thermal, Boyd Corporation, Wieland Microcool, LLC, and Wakefield Thermal. You can also browse the page SC Rank to build your cooperation relationship. These companies offer high-quality, customizable products with proven performance. According to Fortune Business Insights™, the global market for EV battery cooling plates is projected to reach $7.26 billion by 2030, indicating a robust industry with reliable suppliers.

Selecting a trusted supplier ensures you receive components that meet industry standards and your project’s specific needs.

Advanced manufacturing processes like stamping(more), extrusion, continuous brazing, vacuum brazing, HF welding, FSW and CMT enhance the thermal performance and durability of cooling plates. XD Thermal’s continuous brazing increases welding speed by more than 47.3% and enables automated continuous production (600-800mm/min) without defects, resulting in stronger, more reliable cooling plates. It has to be said that continuous brazing is a better choice in terms of output and efficiency.

Choosing products made with these advanced techniques ensures better performance and longer lifespan.

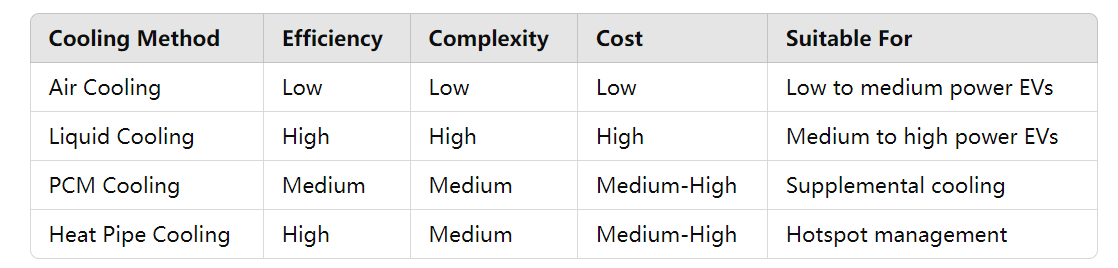

Why choose water cooling plates over other cooling methods?

Water cooling plates offer up to 25% more efficient heat removal compared to air cooling systems. According to research published in the Journal of Power Sources, liquid cooling methods maintain battery temperatures within optimal ranges more effectively, enhancing safety and performance.

Water cooling plates present an ideal solution by providing efficient and precise thermal management without the downsides of complexity and weight seen in immersion cooling. Their direct contact with battery cells allows them to effectively dissipate heat, making them a highly efficient and reliable choice for high-performance EVs.

While air cooling and other alternatives offer viable cooling options, they often fall short in high-performance EV applications. Air cooling, for instance, struggles to manage the thermal load in compact EV battery packs, leading to inconsistent cooling, reduced efficiency, and faster battery wear.

Lightweight battery cooling plates are essential for efficient thermal management in electric vehicles. By preventing overheating without adding unnecessary weight, they enhance performance, safety, and battery lifespan. Incorporating data-backed solutions like water cooling plates can lead to significant improvements in EV efficiency and reliability. This revision includes embedded links that direct readers to relevant sources while maintaining readability and coherence throughout your article.