You may already have some knowledge about the application of cold plates in the field of new energy. However, without a deep understanding of cold plates, you could select or design an inappropriate type, potentially delaying your project. We once worked with a new energy vehicle client in Europe who initially chose an unsuitable type of liquid cooling plate, resulting in significant delays when they had to switch types later. So, what are the primary types of cold plates used in the new energy field?

Knowing the main types of liquid cooling plates is just the beginning. These cold plates play a critical role in thermal management for battery pack systems, involving intricate technical details. To choose or design the right them, you need a deeper understanding. Keep reading together.

The cold plate is a crucial part of the liquid cooling system. It effectively absorbs and transfers heat from the battery module or pack due to its excellent thermal conductivity. Coolant flows through tubes inside the cold plate, efficiently removing the heat. This direct heat conduction and transfer mechanism makes the cold plate essential in managing battery temperatures.

In data centers, effective cooling is crucial due to high power density. Liquid cooling, especially using cold plate systems, efficiently transfers heat from internal components to the outside. This method ensures safe operating temperatures and avoids direct contact between the coolant and sensitive electronics. It also provides precise heat exchange for key components like CPUs and memory.

(the heat exchanger is liquid cooling plate heat exchanger)

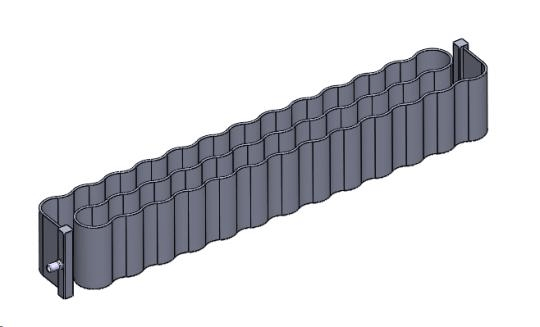

For cylindrical batteries, almost all customers use the side heat exchange solution with serpentine tubes, like the Tesla cylindrical battery heat exchange case. (serpentine tubes instructures)

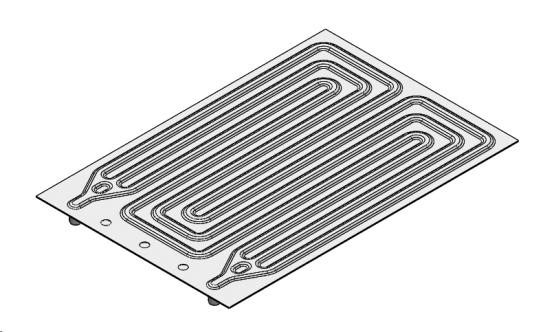

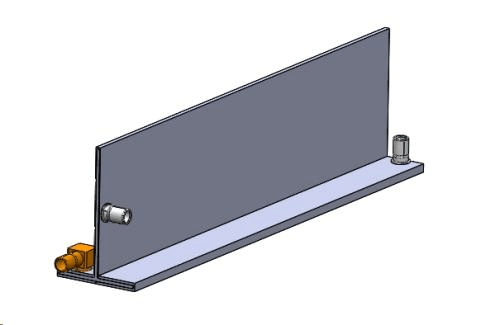

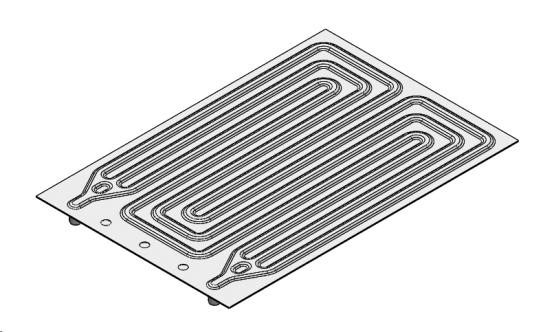

For prismatic batteries, 73.3% of customers opt for liquid cooling plates with bottom heat exchange. Increasingly, many are now also using side heat exchange or multi-sided heat exchange. Side heat exchange involves extruding micro-channel tubes and bending them, similar to serpentine tubes. And multi-surface heat exchange, shown in Figure 3, cools both the bottom and sides simultaneously, greatly improving efficiency. (cold plates instructures)

This utilizes hydroforming technology, a type of stamping process that creates complex yet precise shapes. It is ideal for producing liquid cooling plates that effectively control battery temperature and maintain minimal temperature differences between batteries.

Precise Shapes: Generates complex geometric shapes to optimize heat transfer and cooling efficiency.

Durability: The structure is robust, resistant to high pressure and temperature, suitable for tough environments.

Adaptability: Flexible design can be customized for various equipment sizes.

Efficiency: Short production cycle allows for quick mass production to meet demand.

Aluminum ingots are pressured into multiple metal streams, forming flat or micro-channel tubes through mold gaps. This allows precise control of cooling plate shapes and sizes, enhancing load capacity.

Efficiency and cost-effectiveness: Simple molds used in aluminum extrusion shorten production cycles and reduce costs.

Friction stir welding (FSW) is a solid-state process that uses a rapidly rotating, needle-shaped tool to frictionally heat and soften two metal workpieces without melting them. The materials are then plastically deformed and mixed to create a weld.

High strength: FSW retains over 70% of the original metal’s strength and provides robust welds. Post-weld sanding can produce a seamless finish.

Consistent processing: Specialized tooling and stir needles ensure uniformity across workpieces.

This method involves machining to carve specific shapes and internal channels from a block, allowing for cooling fluid flow. It ensures part stability and durability under extreme conditions.

Highly customizable: Machining technology allows for the creation of liquid-cooled panels tailored to specific shapes and sizes, meeting the unique requirements of various applications.

Durability: Machined cooling plates possess strong mechanical properties and are resistant to wear and corrosion, leading to a longer service life, reduced replacement frequency, and lower long-term costs and maintenance.

In order to make the liquid cold plate have stable thermal conductivity, the thermal interface material will be installed on the surface of the liquid cold plate more often. The thermal interface material has a stable heat conduction efficiency and increases the contact area between the battery and the liquid cold plate. Most thermal interface materials also have some insulation, and silicone pads (one of the mainstream thermal interface materials) can generally achieve a voltage resistance of 3-7Kv.

As one of the most efficient battery thermal management solutions, technological innovation of water cooling plates may focus on the following key areas:

1. Material Innovation: Developing new materials or enhancing existing ones, such as using graphene or composites, to increase thermal conductivity while reducing weight and cost. This enhances the efficiency of cooling plates to meet higher heat dissipation demands.

2. Microchannel Technology: Improving heat exchange efficiency by engineering smaller internal channels within the product, increasing the coolant’s surface area. This allows for quicker absorption and release of heat.

3. Modular and Scalable Design: Creating a modular cold plate system that can be easily expanded or modified to suit various applications, reducing design and production costs and broadening potential uses.

My answer is: Yes, I am very optimistic about the role of artificial intelligence in optimizing liquid cooling plates. Currently, the design of liquid cooling plates uses a variety of tools to test, simulate, and verify the effectiveness of liquid cooling plates. Drawing review and proofreading requires manpower and material resources, and the current computer simulation system for judging working conditions is still relatively time-consuming. status. In the future, some basic, repeatable, computable, and standard work can be completed by AI.

In industrial production, AI may be able to provide more efficient and targeted solutions in the optimized design of cold plate shape, internal cooling channel configuration, fin geometry, inlet and outlet locations, etc., breaking the limitations of some traditional methods.

The key to the application of liquid cooling plates in the new energy field is to improve the thermal management efficiency of the system. I believe this article can help you understand what kind of liquid cooling plates you can choose to meet your project needs. In the future, the intervention of artificial intelligence also heralds unlimited possibilities for design optimization. It has to be said that cold plate technology is not only a challenge for engineers, but also a commitment to the future development of the entire new energy field.

I've worked in battery thermal management for over 5 years, handling lots of international projects. If you're curious about battery liquid cooling products or services, feel free to ask me any questions!