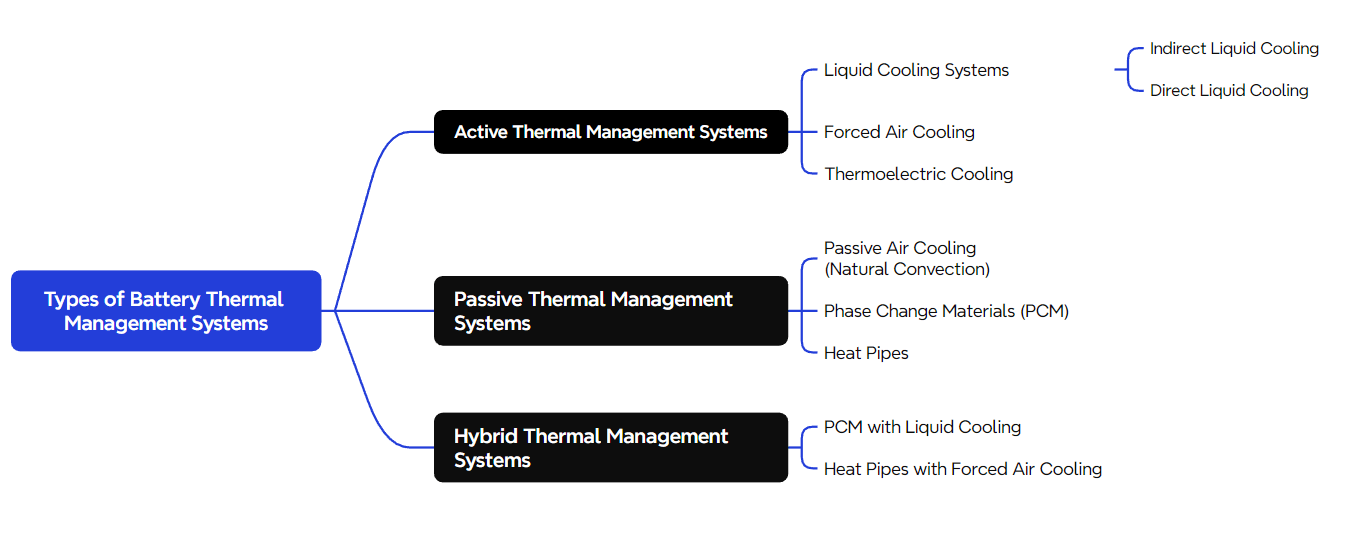

Active Thermal Management Systems

Active systems use external resources (e.g., fans, liquid coolers) to regulate battery temperature. They are more complex systems but offer precise control over the operating conditions of the battery.

Table of Contents

Liquid Cooling Systems

Liquid cooling is one of the most effective methods for managing battery temperatures in electric vehicles (EVs). The coolant, usually a mixture of water and glycol, flows through channels or plates in direct or indirect contact with the battery cells.

The coolant flows through a closed-loop system of pipes or plates that contact the battery cells. The battery cells conduct heat to the coolant. This method prevents the coolant from coming into direct contact with the electrical components, improving safety. The heated coolant then passes through a heat exchanger, where the heat is dissipated to the atmosphere, often with a radiator and fan assembly.

In this method, the battery cells are directly immersed in a dielectric (non-conductive) liquid. This allows for superior heat transfer because the fluid is in direct contact with the cells. You must use special coolants, and there are safety concerns. Direct liquid cooling systems can manage much higher heat loads and are useful in high-performance applications where rapid heat dissipation is critical.

- - High thermal conductivity ensuring efficient heat transfer.

- - Keeps the battery pack at a uniform temperature.

- - Effective in high-temperature environments and high-performance applications.

- - Increased system complexity and cost.

- - Potential risk of coolant leakage, which can affect battery safety.

- - Requires additional components like pumps and heat exchangers.

Tesla Model S and BMW i3 utilize liquid cooling systems to manage their battery temperatures effectively.

Forced Air Cooling

Forced air cooling uses fans to blow air over the battery cells, removing the excess heat through convection. It is a simpler, less expensive approach than liquid cooling but may not be as effective in extreme temperatures.

- - Increased system complexity and cost.

- - Potential risk of coolant leakage, which can affect battery safety.

- - Requires additional components like pumps and heat exchangers.

- - Less efficient heat transfer compared to liquid cooling.

- - May lead to uneven temperature distribution, causing hotspots.

- - Fans consume energy and can produce noise.

The Nissan Leaf and Volkswagen e-Golf have employed forced air cooling systems in their battery packs.

Thermoelectric Cooling

Thermoelectric cooling systems use the Peltier effect, where electric current creates a temperature difference across materials. This effect allows you to both heat and cool the battery pack as required.

- - Precise temperature control.

- - Compact and lightweight design.

- - No moving parts, leading to high reliability.

- - Lower efficiency compared to other cooling methods.

- - Higher energy consumption, affecting vehicle range.

- - More expensive due to specialized materials.