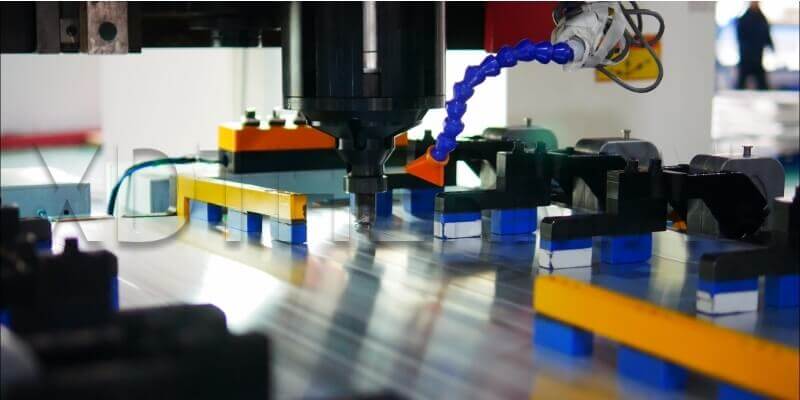

Stamping

Our company specialises in precision stamping technology, allowing you to create customised battery cooling plates and components with accurate dimensions and smooth finishes. This precise process ensures consistent quality and optimal performance for your projects.

Our stamping capabilities include deep drawing, progressive stamping, fine blanking, and compound die stamping, enabling us to meet complex design requirements across various applications.