What makes XD Thermal's CNC process more advanced?

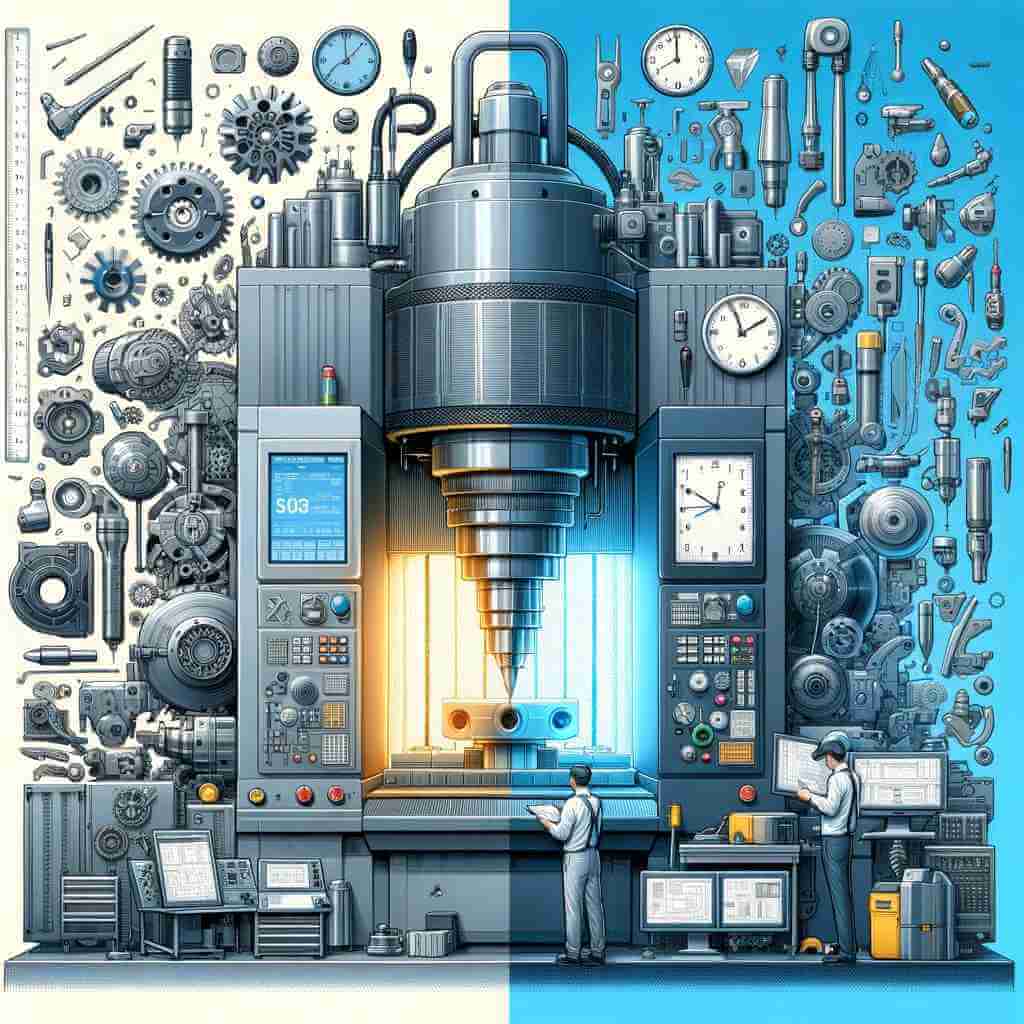

Equipped with automated special-purposed CNC stations. Different processes will be assigned to special stations. Some of them work only for mounting hole drilling, some of them work only for channel carving.

By using special-purposed CNC stations, less fixtures can be achieved. It brings down cycle time, and makes accuracy maintained in one single fixture.By using special-purposed CNC stations, less fixtures can be achieved. It brings down cycle time, and makes accuracy maintained in one single fixture.

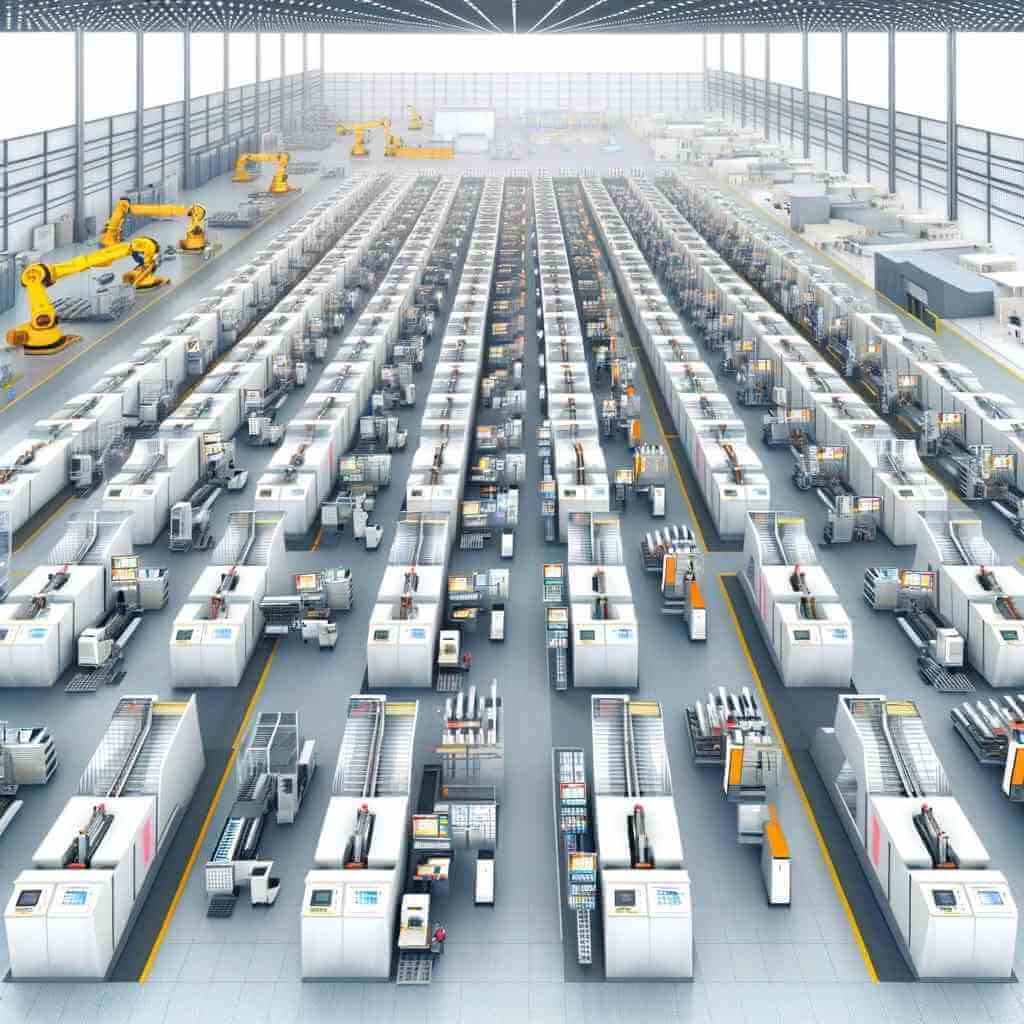

Over 100 CNC stations, medium and large, well guaranteed considerable capacity.

Experienced program engineers text efficient programs to let the CNC process finish with optimal usage of time and material.