The battery production process introduces inconsistencies between individual battery cells, which gradually become more pronounced during actual usage. The performance of batteries is influenced by factors such as charge-discharge cycles, ambient temperature, and discharge currents. As a result, practical battery performance may exhibit deviations from theoretical expectations. During operation, batteries tend to follow a ‘weaker gets weaker, and at a faster rate than the stronger’ trend. This undoubtedly poses significant challenges to battery thermal management and energy conversion.

In one-dimensional designs, where batteries are neatly arranged, the flow direction and battery temperature changes can be observed clearly as the cooling medium flows from left to right. (Temperature is lower near the cooling medium and higher away from it.)

In two-dimensional designs, when multiple rows of batteries are staggered, it becomes less intuitive to determine the flow direction, speed of the cooling medium, and cooling conditions. Which battery experiences a higher temperature rise? Which battery exhibits greater temperature differences? This requires the use of fluid dynamics and heat transfer simulations to make informed judgments.

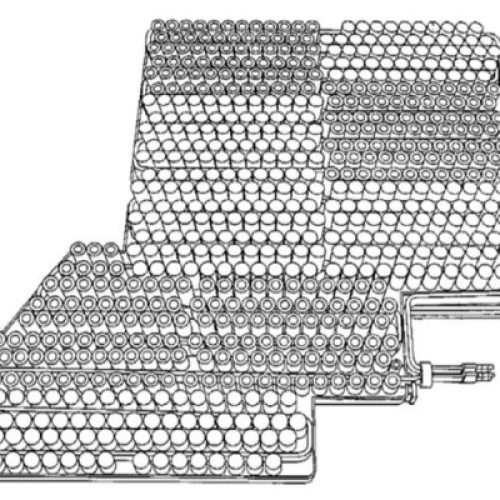

In three-dimensional designs, one must take into account vehicle structure and battery cell arrangement (such as the irregular distribution seen in Tesla’s battery pack, as depicted in the diagram). This complexity adds considerable challenges to the design, simulation, and testing of thermal management systems.

Batteries, despite being unassuming, are remarkably intricate devices. This becomes particularly evident in the realm of new energy vehicles, where they involve disciplines like measurement and control technology, energy conversion techniques, power transformation strategies, system integration, and manufacturing processes. Even though perfect cell uniformity may not exist, we continue to strive for minimal disparities in battery temperatures. This isn’t merely an isolated concern; it’s a systemic challenge that necessitates interdisciplinary collaboration and precision-driven design to tackle.

A deeper understanding of batteries and a grasp of market demands are essential to assist researchers and designers across various stages in crafting products that genuinely meet market needs.