Struggling to obtain precise quotes for custom battery cooling plates? This challenge can lead to project delays and budget overruns. Discover how to streamline the quoting process.

Here’s a step-by-step guide to help you request accurate quotes efficiently.

Before reaching out to suppliers, it’s essential to have a clear understanding of your technical needs for the battery cooling plates, tubes or enclosures.

Specify dimensions, thermal performance requirements, and any unique features. Detailed technical requirements help suppliers provide accurate quotes and suitable solutions tailored to your project.

Defining your technical requirements includes outlining operating conditions like temperature ranges and environmental factors. Consider additional features such as integrated sensors or specific fluid compatibility. The more precise you are, the easier it will be for suppliers to assess production feasibility and cost implications.

It doesn’t matter if you just want to get a head start, a professional supplier will provide you with some data sheets to assist you in refining the basic parameters needed for your quote.

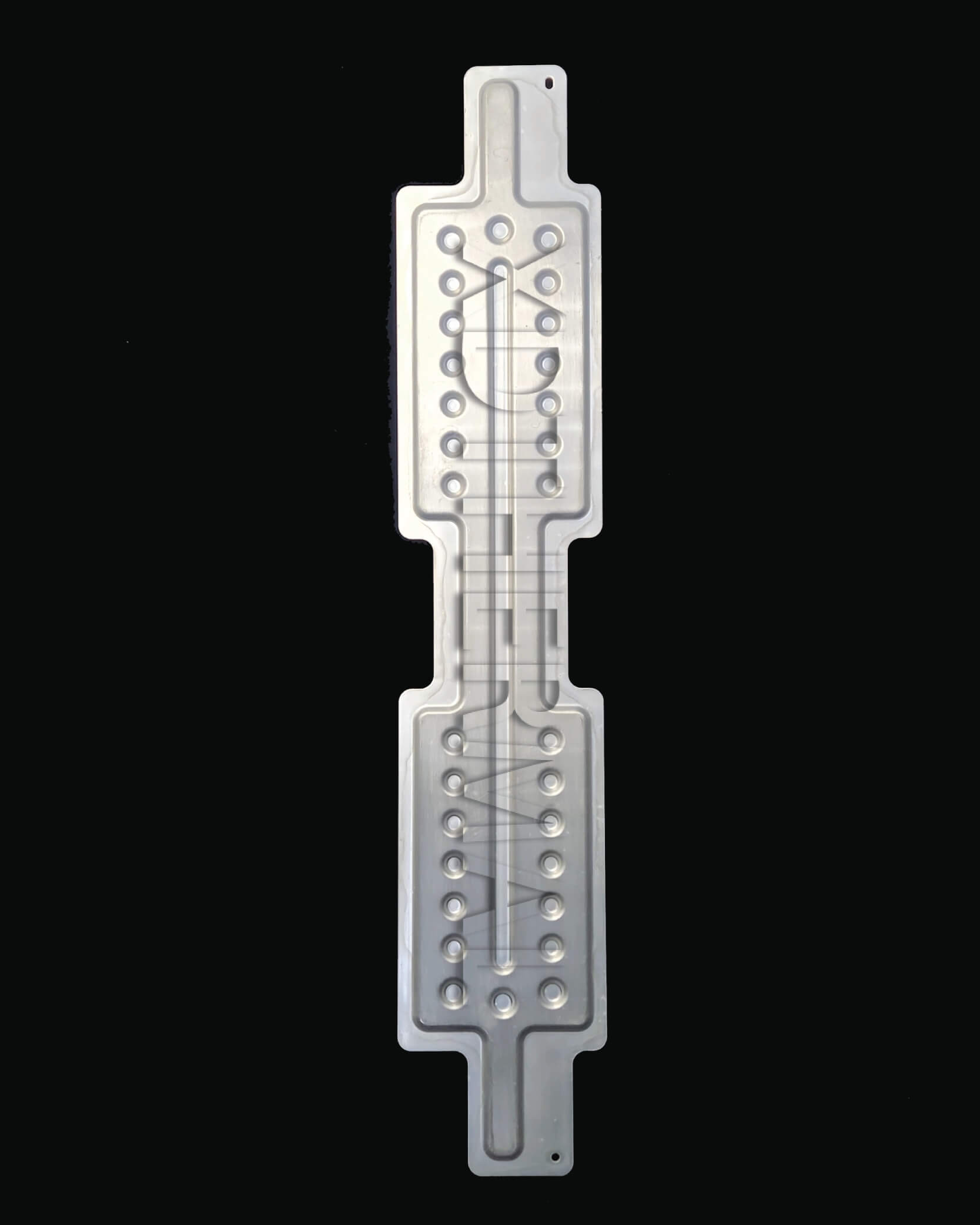

Design drawings are crucial for suppliers to visualize and accurately estimate the cost of your custom cooling plates.

Include comprehensive CAD drawings with all necessary dimensions and annotations. Detailed drawings enable suppliers to calculate material usage and machining requirements, leading to more precise quotes. This evaluation cycle will be very short you know, and sometimes a quote can even be provided on the same day.

If you have 3D models or prototype samples, share them with your suppliers. This aids in identifying potential manufacturing challenges early on. Ensure your drawings comply with industry standards, and consider involving the supplier’s engineering team for collaborative design enhancements.

What if you need a quote but don’t have detailed design drawings yet?

Even without drawings, you can obtain a preliminary quote by providing detailed descriptions of your requirements, including dimensions, performance criteria, and intended applications. Engage with suppliers who offer collaborative design services. Usually this quotation time will be extended as the difficulty of the project increases.

After clarifying the requirements, it is more important to understand the production process and attention to details required for the products you purchase, because this profoundly affects the procurement cost and delivery time, and is also a reference for you to evaluate the supplier’s capabilities. Maybe you think Just send an inquiry first and wait for the supplier to tell you, but that’s not the case.

Material selection and manufacturing processes significantly impact the cost and performance of battery liquid cooling parts.

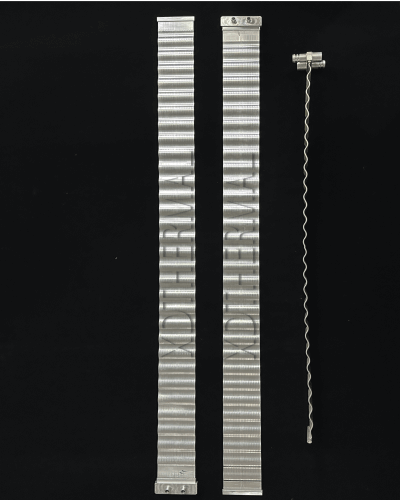

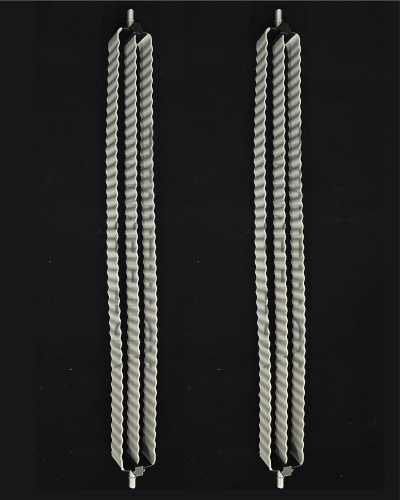

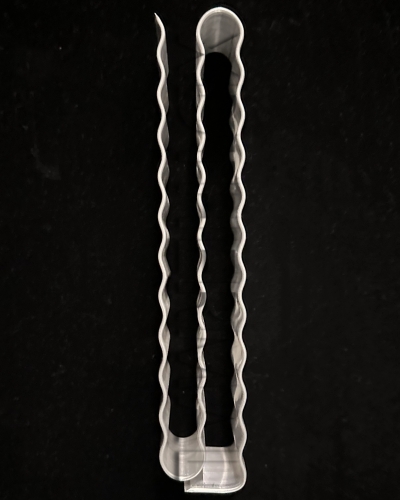

Discuss material options like aluminum or copper and manufacturing processes such as extrusion, machining, or vacuum brazing. Understanding these factors helps in obtaining quotes that match your quality and budget expectations.

Different materials offer various thermal properties and cost implications. For instance, aluminum is lightweight and cost-effective, while copper provides superior thermal conductivity. Processes like friction stir welding or hydroforming (stamping) may affect lead times and tooling costs. Collaborate with suppliers to choose the best combination for your application.

Among the projects we evaluated, stamping is more common, has a short processing cycle, and is more cost-effective in mass production. With the advent of the “large cylindrical battery era”, the extruded serpentine tube solution is becoming more and more prominent. In addition to our common 4680, 21700, 6061, many special-sized cylindrical batteries cooling solutins have entered the proofing and even mass production stages.

Many customers often ask “What kind of liquid cooling solution is suitable for me?” when communicating for the first time? This is a good question, because it examines the comprehensive strength of a supplier. See if he can match the size, heat exchange efficiency, power and budget range of your equipment to provide reasonable and effective solutions in a short time. Don’t worry.

At XD THERMAL, we have a professional engineering team from design and development to mass production to support evaluation and recommend the optimal solution.

Supplier qualifications ensure they can meet your project’s quality and compliance standards.

Verify if suppliers have certifications like IATF 16949 and robust testing capabilities. Certified suppliers are more likely to deliver reliable products and understand international project requirements.

Ask about the supplier’s quality control processes and whether they offer inspections like flow resistance or pressure testing. A supplier with comprehensive testing facilities can save time and costs associated with third-party testing. Experienced suppliers can also provide valuable insights into regulatory compliance for different markets.

Time is often a critical factor in project planning and execution.

Communicate your project timelines clearly, including prototype development and mass production schedules. This allows suppliers to allocate resources effectively and provide quotes that align with your delivery needs.

Understanding the supplier’s lead times for tooling, sampling, and production helps in scheduling and avoids delays. Discuss potential bottlenecks and plan for contingencies. Long-term partnerships with suppliers who offer flexible and fast product development can be advantageous for ongoing projects.

Comparing quotes from different suppliers helps you find the best fit for your project.

Request quotes from several vendors and assess them based on pricing, capabilities, and experience. This evaluation ensures you select a supplier who offers the best value and meets your project requirements.

Consider factors like the supplier’s track record, customer testimonials, and responsiveness during the quoting process. Engaging with multiple suppliers provides insights into market pricing and available technologies. It also encourages competitive pricing and can reveal potential red flags with certain vendors.

Protecting your proprietary information is crucial when sharing project details.

Before exchanging sensitive information, sign NDAs with potential suppliers. This legal agreement ensures that your designs and ideas remain confidential.

An NDA fosters trust between you and the supplier, encouraging open communication without the risk of information leaks. Ensure the NDA is mutually beneficial and consult legal counsel if necessary. A well-drafted NDA can protect your intellectual property throughout the collaboration.

Suppliers with extensive experience can offer valuable insights to improve your design and reduce costs.

Engage suppliers early in the design process to benefit from their expertise in materials, manufacturing processes, and industry standards.

Collaborative relationships can lead to innovative solutions, optimized designs, and cost savings. Suppliers may suggest alternative materials or methods that enhance performance and manufacturability. Their insights can help you avoid common pitfalls and streamline the production process.

Focusing solely on initial costs may overlook long-term expenses.

Evaluate the total cost of ownership, including maintenance, lifecycle performance, and potential downtime. An initially cheaper option might incur higher costs over time.

Discuss warranty terms, after-sales support, and service capabilities with suppliers. A reliable product with robust support can offer better value than a lower-priced alternative with limited assistance. Considering the long-term implications ensures you make a financially sound decision.

By thoroughly preparing and engaging with suppliers strategically, you can secure accurate quotes for custom battery cooling plates, ensuring your project’s success.