Project Contact:

Chris

+86 193-5550-1188

info@xdthermal.com

Battery trays are essential components of the power system in new energy vehicles, specifically designed to support, secure, and protect batteries. This ensures their safe and stable installation in vehicles or energy storage systems. Being crucial to the safety of electric vehicle battery systems, battery trays are highly customizable. They offer robust support, waterproofing, dust resistance, fire prevention, heat diffusion control, and anti-corrosion capabilities.

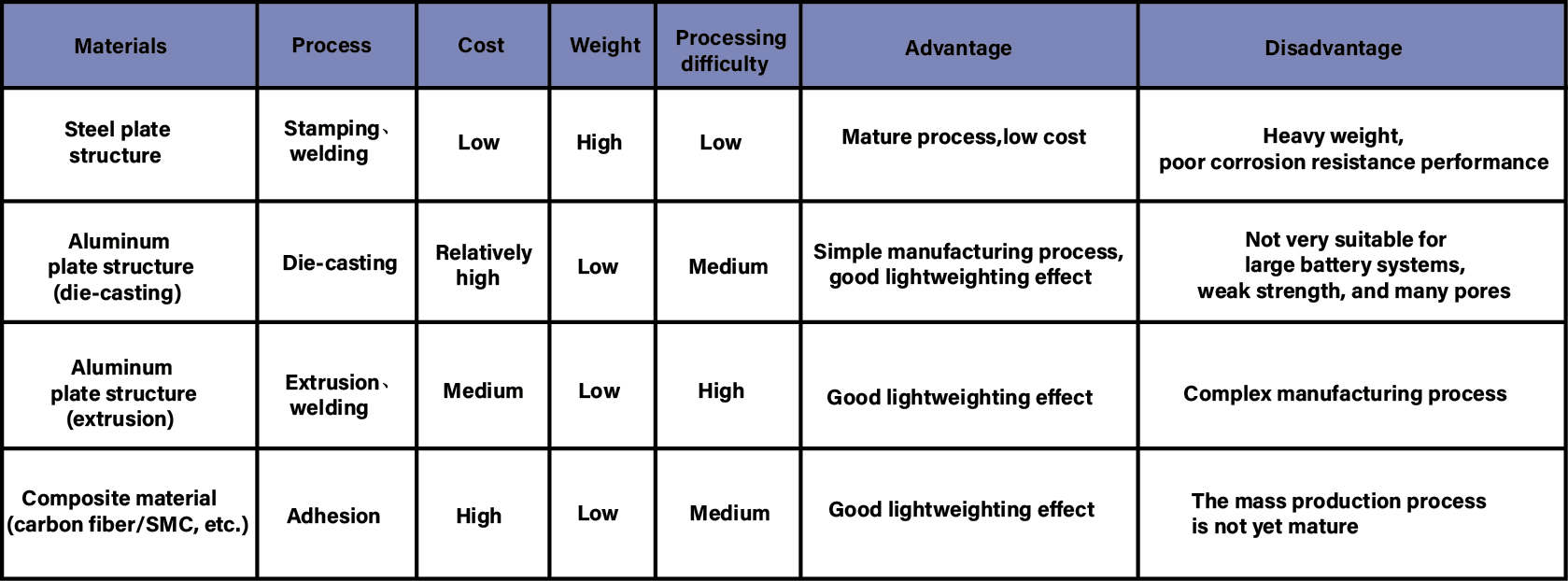

Initially made from steel, battery trays in electric vehicles have evolved to aluminum alloy trays, aiming for lighter and more efficient metal alloy designs. This evolution is driven by the need for lighter vehicles, as electric cars are heavier than traditional fuel vehicles and strive to match their mileage range

Steel battery trays, made primarily from high-strength steel, play a key role in the battery systems of new energy vehicles.

Advantages:

● Cost-effective: Offers manufacturers a cost advantage.

● Excellent processing and welding capabilities: Simplifies and adds flexibility to the manufacturing process.

● Strong resistance to stone impacts: Adapts to various road conditions, enhancing battery safety.

Disadvantages:

● Heavier weight: Affects the driving range negatively.

● Lower rigidity: Prone to deformation under pressure, potentially damaging the battery and increasing fire risks.

● Poor corrosion resistance: Leads to internal battery damage

Cast aluminum battery trays are single-piece structures typically used in smaller energy battery packs.

Advantages:

● Single-piece molding simplifies the manufacturing process.

● Flexible design options to meet diverse requirements, allowing greater design freedom.

● High overall mechanical performance ensures good structural stability.

● Lightweight design reduces the overall vehicle weight, enhancing range.

● No Need for Welding, improving product reliability and durability.

Disadvantages:

● Poor Product Seal: Prone to Defects Such as Undercasting, Cracks, Cold Shut, Dent, Porosity, etc

● Low elongation rate, more likely to deform upon impact.

● Not suitable for large-capacity battery trays

Extruded aluminum alloy battery trays are a popular design choice, assembled and processed from profiles to meet varying requirements.

Advantages:

● Flexible design: Accommodates various application needs.

● Convenient processing: Enhances production efficiency.

● Easily modifiable: Adapts to different battery sizes and vehicle models.

● High rigidity: Offers the strength and stability required for battery components.

● Vibration resistance: Maintains battery stability under different road conditions.

● Resilient to compression and impact: Ensures safety of the battery components.

Disadvantages:

● Complex welding process: Involves multiple welding points, adding to the complexity.

● Increases manufacturing difficulty.

● Higher cos

Extruded aluminum alloy battery trays are a popular design choice, assembled and processed from profiles to meet varying requirements.

Advantages:

● Flexible design: Accommodates various application needs.

● Convenient processing: Enhances production efficiency.

● Easily modifiable: Adapts to different battery sizes and vehicle models.

● High rigidity: Offers the strength and stability required for battery components.

● Vibration resistance: Maintains battery stability under different road conditions.

● Resilient to compression and impact: Ensures safety of the battery components.

Disadvantages:

● Complex welding process: Involves multiple welding points, adding to the complexity.

● Increases manufacturing difficulty.

● Higher cos

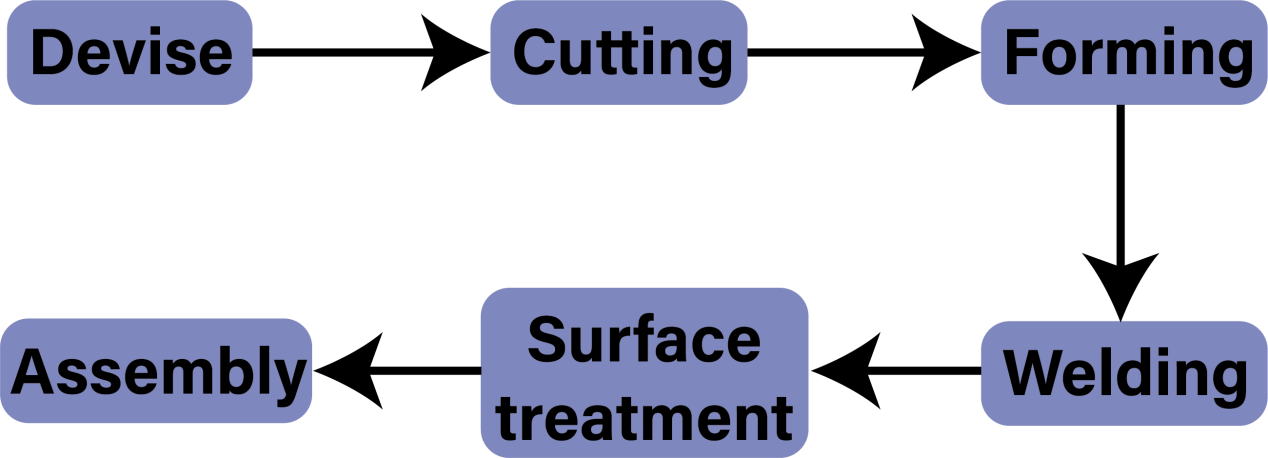

The joining techniques for battery trays, especially in extruded aluminum alloy trays, have advanced significantly. We now use sophisticated welding technologies like Friction Stir Welding (FSW), TIG, MIG, CMT, and mechanical connection methods like bolting. These innovations ensure stronger and more reliable battery trays, enhancing production efficiency and providing robust support for electric vehicle development.

Friction Stir Welding (FSW) is a key method where a high-speed rotating tool generates heat through friction, melting the material locally. As the tool moves along the joint, the softened material flows from the front to the back under the tool’s rotational force, forming a dense solid-phase weld seam.

Advantages:

● Low risk of workpiece deformation.

● High efficiency: capable of welding long seams, large sections, and in varied positions in one go.

● Convenient operation: allows for mechanization and automation, simple equipment, low energy consumption, high effectiveness, and minimal environmental requirements.

● Low cost: no need for additional welding wire, no requirement to remove oxidation film before welding aluminum alloys, and no need for protective gas.

● Wide range of materials can be welded.

● Safe process: free from pollution, smoke, and radiation.

Disadvantages:

● Workpieces must be rigidly fixed with a backing plate.

● Difficult to repair weld seams.

● Tool design, process parameters, and mechanical performance data are limited to a narrow range of alloys.

● Performance improvements needed in specialized areas considering corrosion resistance, residual stress, and deformation.

● Welding speed is not very high.

● Rapid wear and tear of the stirring head.

Fusion welding, often used for connecting the frames of battery trays, is particularly necessary at the frame’s corners where Friction Stir Welding is impractical. This process typically involves methods like TIG, MIG, and CMT, and includes arc welding at the corner joints.

Advantages:

● Broad application: Ideal for welding the corners of the frame.

● High adaptability: Especially suitable for steel battery trays.

Disadvantages:

● Increased heat input: This can compromise the strength of the weld.

● Risk of deformation.

● Porosity issues: Can lead to potential leakage in the tray.

Bolted connections are mechanical fastenings using bolts and nuts to join components, typically used where frequent disassembly and replacement are necessary. The basic principle is to pass a bolt through the component holes and secure it with a nut, thereby achieving a tight and stable connection

Advantages:

● Easy to dismantle: Ideal for parts requiring regular maintenance.

● Highly flexible: Suitable for components of various sizes and shapes.

Disadvantages:

● Prone to loosening: Bolted connections can become loose over time.

● Requires regular checks: Increases the maintenance workload.

Riveting is a mechanical joining method that uses rivets and rivet nuts to permanently connect two or more parts. In this process, a rivet is inserted through holes in the components, and the rivet nut is compressed, causing it to expand and create a strong joint.

Advantages:

● Relatively easy to dismantle for parts that are not frequently replaced.

● Neat appearance without obvious threads or protrusions.

Disadvantages:

● Potential for loosening during operation.

● Requires regular maintenance and inspection.

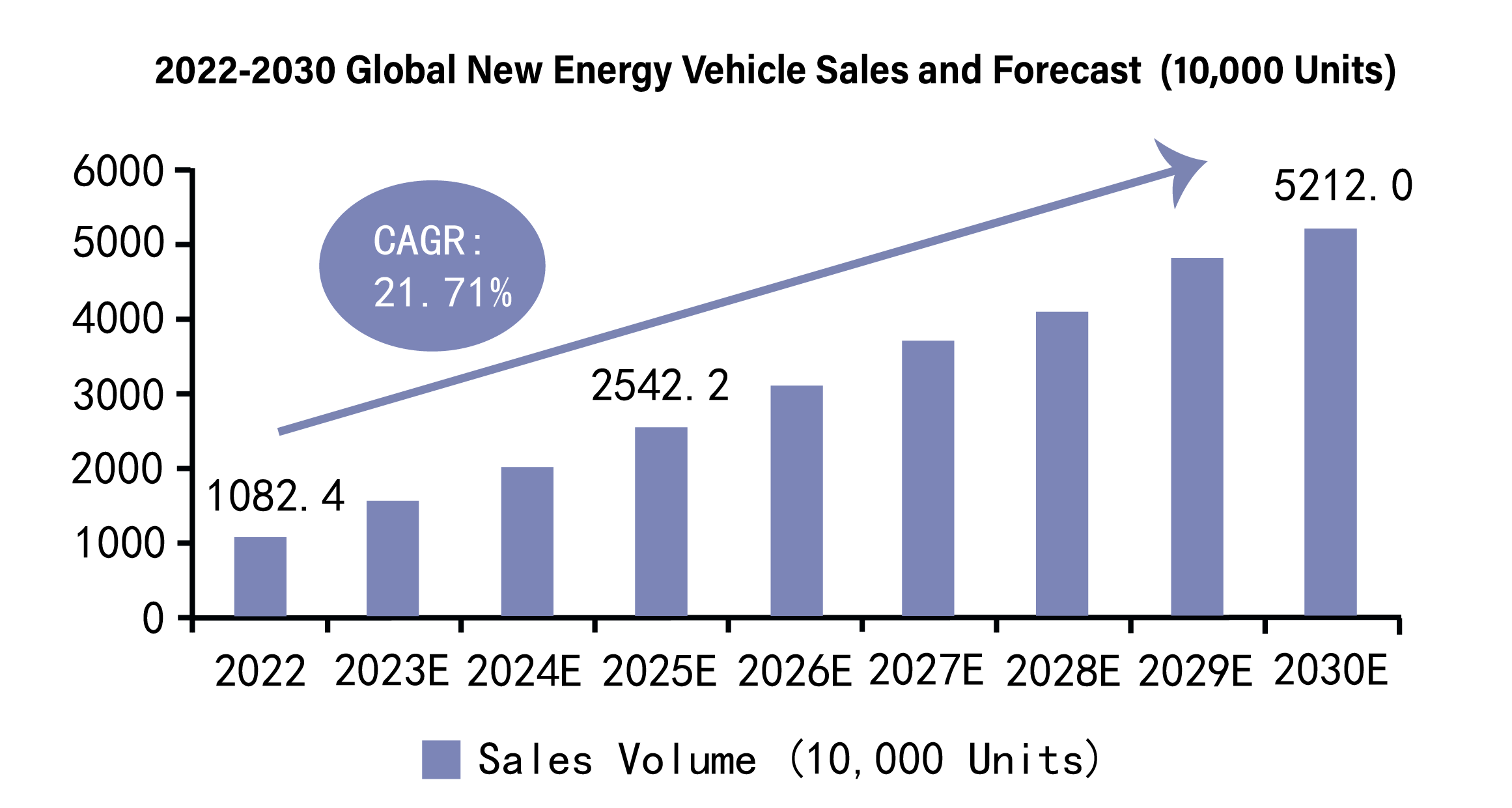

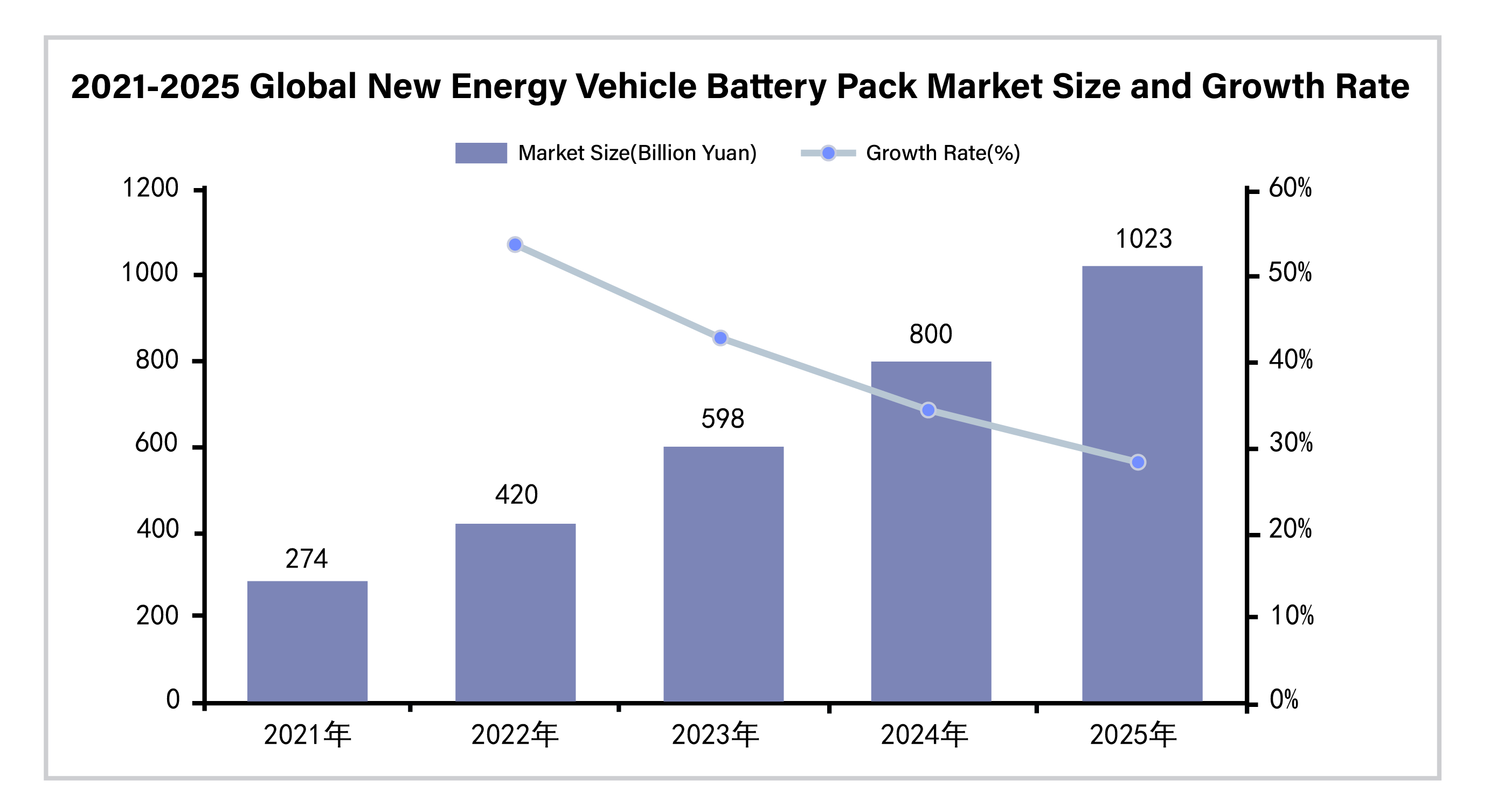

The evolution of battery enclosures in new energy vehicles is a strategic adaptation to growing environmental and efficiency demands. Initially favoring steel for its simplicity and cost, the industry has shifted towards lighter aluminum alloys and advanced manufacturing techniques. This change aligns with the global trend towards sustainable transportation. With predictions indicating a rapid increase in new energy vehicle sales, reaching approximately 52 million by 2030, there’s a corresponding surge in the battery tray market. This growth reflects not just technological advancements but a broader commitment to sustainable automotive solutions, driving innovations in battery enclosure design and production to meet escalating global demands.