Las placas frías de microcanales son cada vez más esenciales en el diseño y la gestión de los vehículos eléctricos (VE). gestión térmica de baterías sistemas. Los ingenieros mecánicos y los integradores de baterías confían en estas innovadoras soluciones de refrigeración líquida para mantener temperaturas óptimas, mejorar el rendimiento y prolongar la vida útil de las baterías de los vehículos eléctricos. Comprender los entresijos del diseño de placas frías de microcanales es crucial para una integración eficaz del sistema de gestión térmica de baterías de vehículos eléctricos.

Las placas frías de microcanal están diseñadas con pequeños canales de precisión que facilitan una transferencia de calor eficiente en los sistemas de gestión térmica de las baterías de los vehículos eléctricos. Mediante el uso de refrigeración líquida, estas placas frías absorben y disipan el calor generado por las celdas de la batería, garantizando un rendimiento y una seguridad constantes. Esto las convierte en un componente crítico en la gestión térmica de los vehículos eléctricos de alto rendimiento.

Exploremos las ventajas específicas, las consideraciones de diseño y las técnicas de integración de las placas frías de microcanales en los sistemas de gestión térmica de baterías de vehículos eléctricos.

Las placas frías de microcanal ofrecen varias ventajas que las hacen ideales para su uso en sistemas de baterías de vehículos eléctricos:

1. Gestión térmica mejorada:

Las placas frías de microcanal proporcionan una disipación eficaz del calor, lo que es fundamental para mantener la temperatura óptima de la batería. Esto garantiza que la batería funcione dentro de su rango térmico ideal, evitando el sobrecalentamiento y mejorando el rendimiento general. Por ejemplo, el diseño de una placa fría monofásica de microcanal alcanzó una resistencia térmica media de 0,112 K/W, lo que demuestra una importante capacidad de gestión del calor (Dede, 2014).

2. Rendimiento y duración de la batería mejorados:

Al mantener las celdas de la batería a una temperatura constante, las placas frías de microcanal ayudan a prolongar la vida útil de la batería. Esto se traduce en una mayor fiabilidad y vida útil del vehículo eléctrico. Los diseños modulares permiten distintas configuraciones para optimizar el rendimiento de la refrigeración, lo que demuestra la flexibilidad a la hora de abordar distintas necesidades de gestión térmica (Zhou y otros, 2015).

3. Seguridad y fiabilidad en entornos de alta tensión:

Una gestión térmica eficaz es crucial para la seguridad de las baterías de los vehículos eléctricos. Las placas frías de microcanales ayudan a evitar el desbordamiento térmico, una situación que puede provocar el fallo de la batería o incluso incendios. La selección de los refrigerantes adecuados y las configuraciones de diseño pueden influir significativamente en el rendimiento térmico e hidráulico de las placas frías (Hoang et al., 2021).

Las placas frías de microcanales se integran en diversos componentes de los vehículos eléctricos para optimizar la gestión térmica:

Integración con pilas: Las placas frías se utilizan para enfriar las celdas individuales de la batería, garantizando una distribución uniforme de la temperatura en todo el paquete de baterías.

Uso en refrigeración de electrónica de potencia: Además de las celdas de las baterías, las placas frías de microcanales también se utilizan para refrigerar componentes electrónicos de potencia, como inversores y unidades de control, que son fundamentales para el funcionamiento de los vehículos eléctricos.

Papel en el mantenimiento de temperaturas de funcionamiento óptimas: Al gestionar el calor generado durante el funcionamiento, las placas frías de microcanal ayudan a mantener las temperaturas de funcionamiento óptimas necesarias para un rendimiento eficiente y seguro de todo el sistema EV.

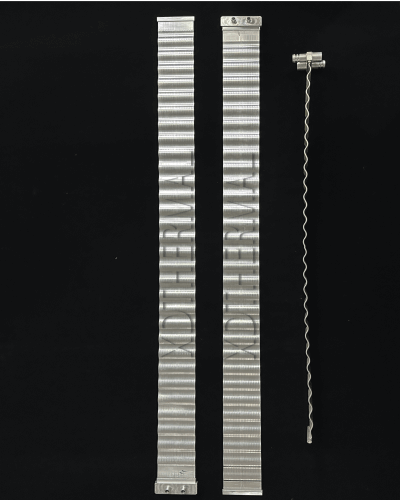

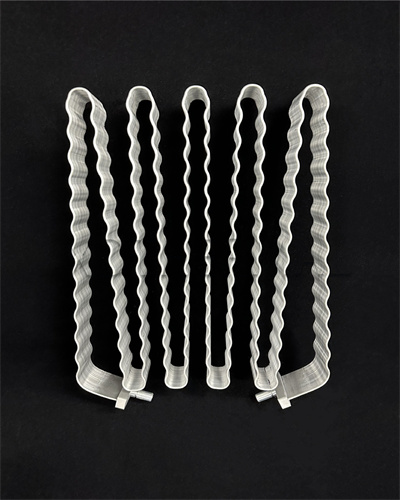

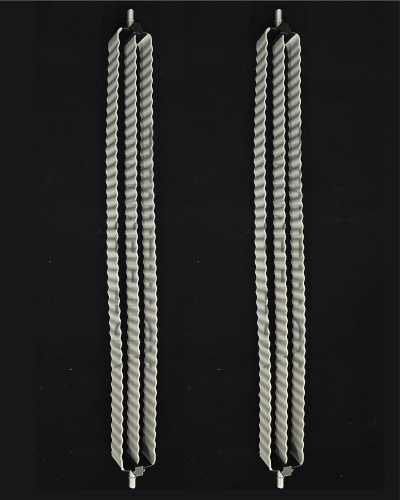

Existen varios tipos de tubos de refrigeración cilíndricos con microcanales utilizados en los sistemas de baterías de los vehículos eléctricos, cada uno de ellos adecuado para aplicaciones diferentes:

Existen múltiples tipos de tubos de refrigeración. Sin embargo, puede haber varios pasos que son comunes:

Preparación del material: Por ejemplo, la esquila.

Canal de flujo/estructura interna: Por ejemplo, extrusión.

Procesamiento de conectores/accesorios: Por ejemplo, entrada y salida.

Soldadura: Por ejemplo, soldadura fuerte, FSW, CMT.

Tratamiento de superficies: Por ejemplo, pulido, revestimiento aislante.

Pruebas y verificación.

Para integrar con éxito las placas frías de microcanales en los sistemas de baterías de los vehículos eléctricos, es necesario tener en cuenta varias consideraciones de diseño:

Materiales comunes: Cobre y aluminio: El cobre y el aluminio son los materiales más utilizados para las placas frías de microcanales debido a su excelente conductividad térmica y a su facilidad de fabricación.

Ventajas e inconvenientes para las aplicaciones de VE: El cobre ofrece un rendimiento térmico superior, pero es más pesado y más caro que el aluminio. El aluminio, por su parte, es más ligero y económico, pero su conductividad térmica es inferior a la del cobre. La elección del material depende de los requisitos y limitaciones específicos del diseño del VE.

Para integrar con éxito las placas frías de microcanales en los sistemas de baterías de los vehículos eléctricos, es necesario tener en cuenta varias consideraciones de diseño:

Diámetro hidráulico y configuración del canal: El diseño de los microcanales, incluidos su diámetro hidráulico y su configuración, influye significativamente en la eficacia de la refrigeración. Optimizar estos parámetros es esencial para una transferencia de calor eficaz.

Compatibilidad con la arquitectura de la batería: El diseño de la placa fría debe ser compatible con la arquitectura general del pack de baterías, garantizando una integración perfecta y una gestión térmica eficaz.

Garantizar la eficacia de las vías de refrigeración líquida: El diseño debe garantizar que las vías de refrigeración líquida sean eficientes y no introduzcan excesivas caídas de presión o restricciones de flujo.

La integración de placas frías de microcanales en los sistemas de baterías de vehículos eléctricos presenta varios retos:

Equilibrio entre la eficiencia de la refrigeración y las limitaciones de peso y espacio: Aunque las placas frías de microcanales ofrecen una alta eficiencia de refrigeración, deben diseñarse para adaptarse a las limitaciones de peso y espacio del VE.

Fabricación y costes: El proceso de fabricación de placas frías de microcanales puede ser complejo y costoso. Es crucial encontrar técnicas de fabricación rentables sin comprometer el rendimiento.

Fiabilidad y durabilidad en condiciones variables: Las placas frías deben ser duraderas y fiables, capaces de funcionar en una amplia gama de condiciones y temperaturas de funcionamiento. La fiabilidad de estos sistemas puede mejorarse abordando cuestiones como la corrosión, como demuestran los estudios sobre diseños de bucles de flujo para captar el comportamiento de la corrosión (Kini et al., 2020).

Las placas frías de microcanal ofrecen claras ventajas sobre otros métodos de refrigeración:

Aunque la refrigeración directa al chip es eficaz, la refrigeración por microcanales proporciona una gestión térmica más uniforme y eficiente, sobre todo para los paquetes de baterías más grandes.

La refrigeración líquida, como la que proporcionan las placas frías de microcanales, es significativamente más eficiente que la refrigeración por aire, lo que permite una mejor disipación del calor y gestión térmica.

Las placas frías de microcanales ofrecen un rendimiento de refrigeración superior, lo que las convierte en la opción preferida frente a los métodos tradicionales para aplicaciones de alto rendimiento y seguridad crítica en vehículos eléctricos.

Las placas frías de microcanales desempeñan un papel vital en la gestión térmica de los sistemas de baterías de los vehículos eléctricos, ofreciendo importantes ventajas en términos de rendimiento, seguridad y longevidad. Al comprender los principios de diseño y las técnicas de integración, los ingenieros y los integradores de paquetes de baterías pueden tomar decisiones informadas que mejoren la eficiencia y la fiabilidad de los vehículos eléctricos. Adoptar esta tecnología es esencial para avanzar en las capacidades y prestaciones de los futuros vehículos eléctricos.

He trabajado en la gestión térmica de baterías durante más de 5 años, ocupándome de muchos proyectos internacionales. Si tiene curiosidad sobre los productos o servicios de refrigeración líquida de baterías, ¡no dude en hacerme cualquier pregunta!