Project Contact:

Chris

+86 193-5550-1188

Chris@xdthermal.com

What Is ESS Battery Enclosure

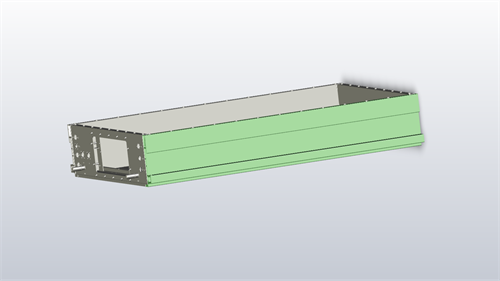

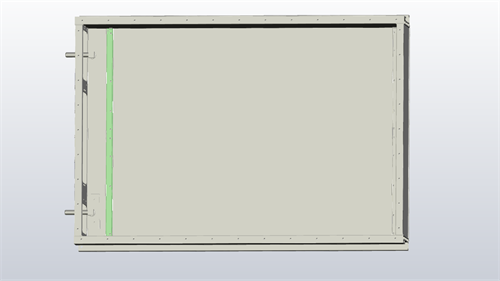

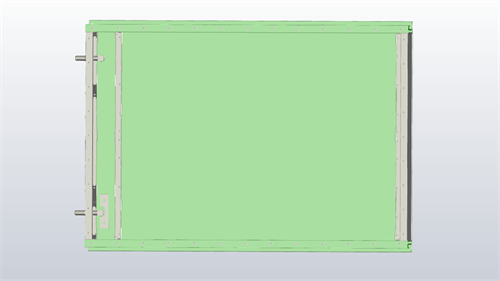

Battery enclosure is also known as the battery box (battery housing / battery tray) and is one of the most important components in Battery Pack. It provides a space, which is mechanically strong and water-dust proof, for battery cells, thermal management systems, BMS and so on. Besides Cells, BDU, BMS and PCS, battery enclosure is another important cost influencer in ESS system.

ESS Battery enclosure design followed the same concept and structure from automotive industry in earlier years. By knowing the difference of use cases, ESS Battery enclosure evolved with its own unique features.

Primary Focus of Battery Enclosures

Materials

The use of advanced materials and material composition has significantly improved the design and structure of battery packs in ESS(energy storage system). Now two main materials used, Aluminum and Steel.

While steel is characterized by simple manufacturing processes and lower costs, it exhibits higher density and greater mass. With the evolution of lightweight design principles, aluminum alloys, owing to their lower density, lightweight nature, corrosion resistance, high strength, excellent die-casting capabilities, and greater sustainability, are enjoying a larger market share.

Structure(in details)

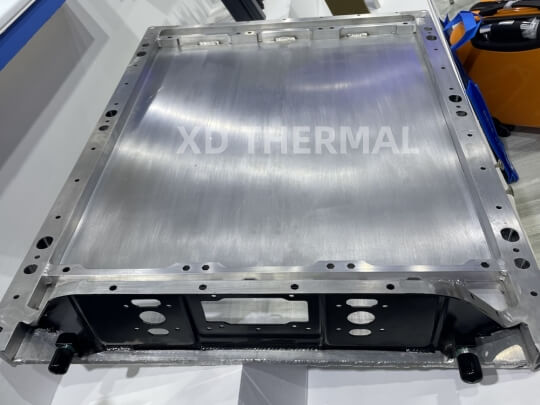

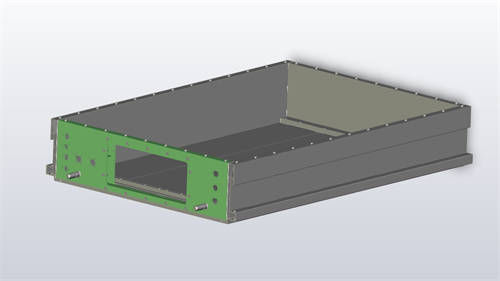

Normally, one ESS Battery case consists of top cover, lower case, cooling plate, frame panel, beams and bottom plate.

The design of battery enclosures should be based on the overall spatial structure and layout of the energy storage system. For instance, whether it is necessary to integrate the water-cooling plate with the bottom protective plate to reduce costs. What position and dimensions should be chosen for the beams to enhance heat transfer efficiency? How much space should be left to ensure proper integration of battery cells with other electronic components.

Workmanship

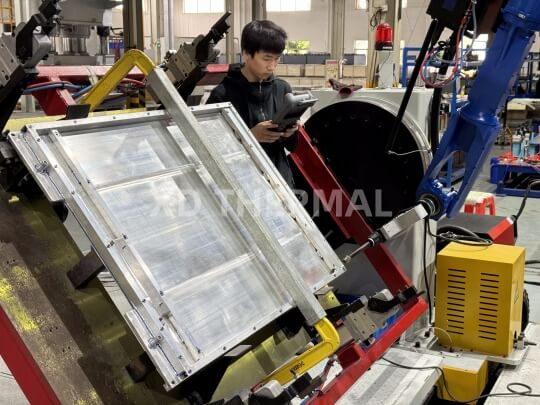

👉 AL profile + Welding: Mainsteam choice, balanced in cost, productivity and flexibility.

👉 AL profile + hydro forming + Welding: Optimized in thermal performance and bigger room in weight reduction.

👉 Die casting + Machining: Higher productivity with a much higher day one investment.

So far, AL profile plus welding is most preferred way of ESS battery case production. With flexible combination of extruded beams and cooling plates, expansion and upgrade of existing product can be possible. For example, 1P52 configuration can share most of its toolings for 2P52S or 1P104S.

The Evolution of Energy Storage System Enclosures

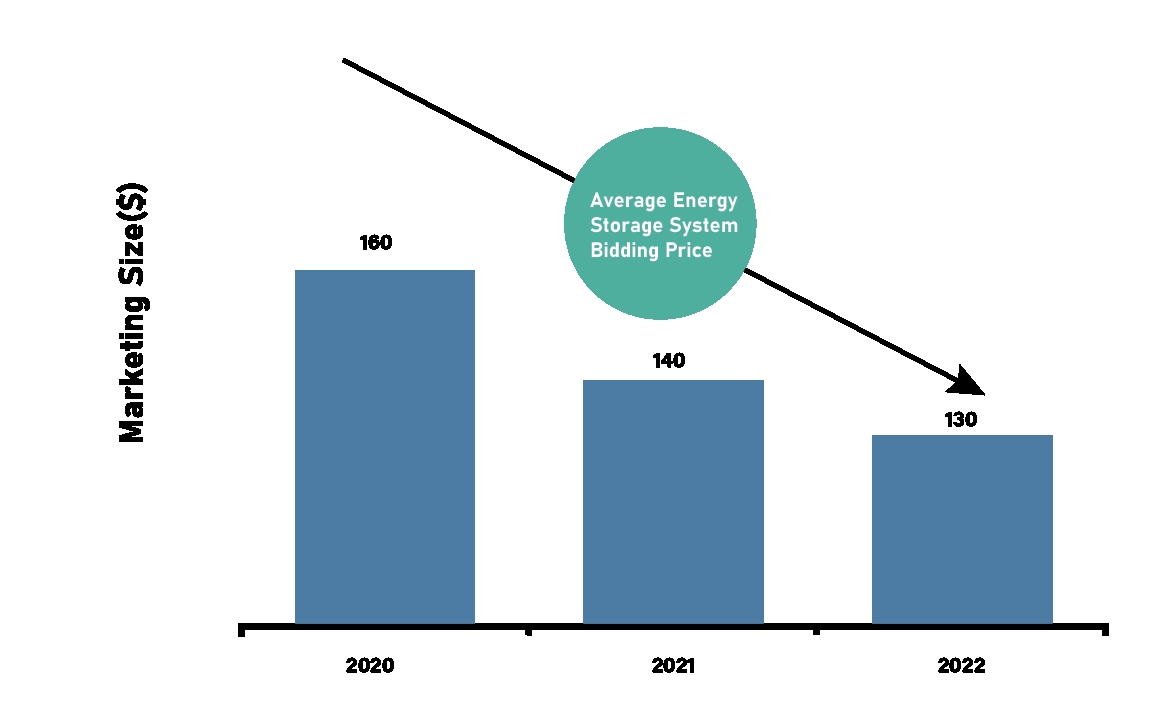

Per kWh cost between 2020-2022 for battery pack was 130-160 USD. This year, it reached to new low record, most of the packs quote lower than 68.5 USD per kWh in China ESS biddings.

Cost control is a non-avoidable topic presented in front of ESS business participants. That’s why design upgrade and structure optimization of battery case is necessary in very high level of priority.

Solutions to become competitive

🔧 Optimized in overall structure

Cooling plates + assembly frame + PCM. By having this new structure, material saved, and can be flexible in protection level from IP55-IP67.

🔧 Performance in automotive level

Deployed hydro formed cooling plates, which design and made with delicate cooling channels. It can support charge/discharge higher than regular 1C, maintain excellent battery temperature.

🔧 Expandable toolings

When develop series of products, making toolings and design compatible among projects will significantly improve dev timeline and cost control.

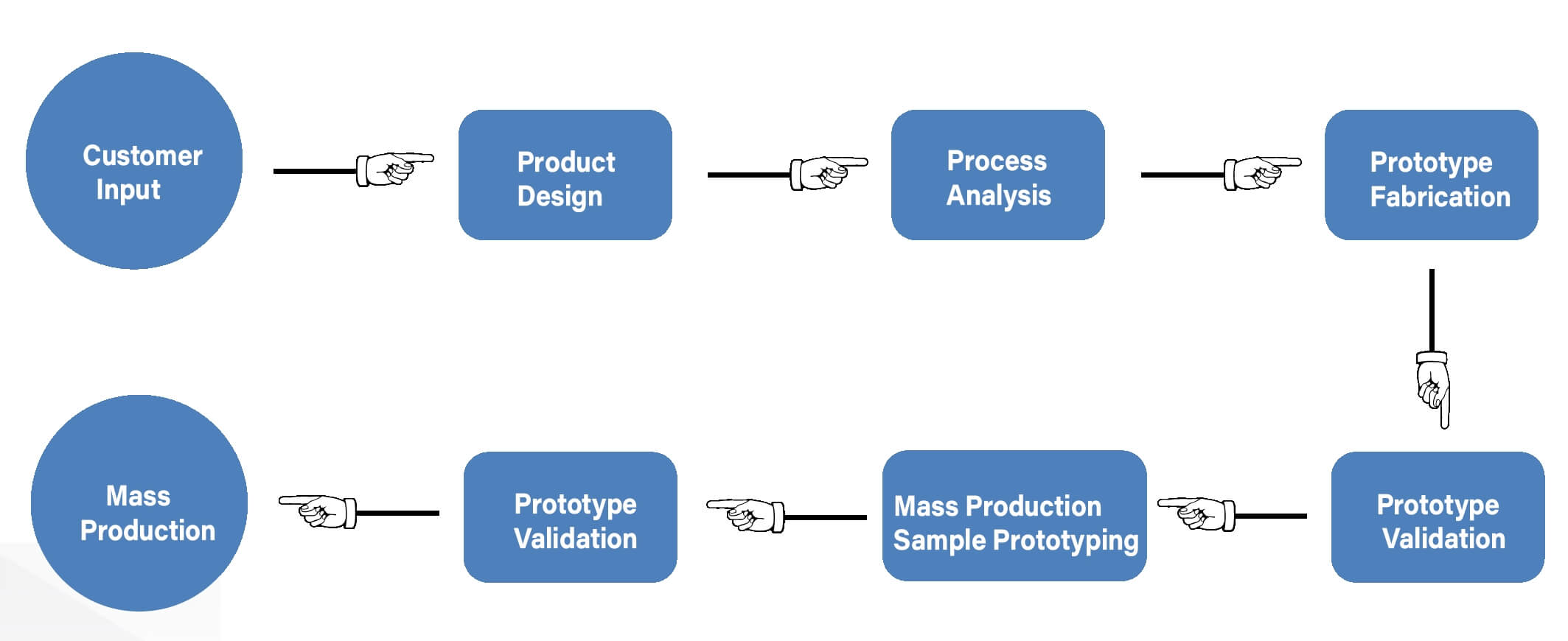

Project Development Process

The energy storage industry is currently at a crucial juncture, transitioning from a growth phase to a mature phase. A well-established and trustworthy enclosure development process can significantly enhance the efficiency of energy storage project advancement

ESS Battery Case in XD Thermal Technology Co Ltd

XD Thermisch has very rich experience in both Automotive and ESS industry, that’s why XD could blend technical inspirations from both fields. Experts from XD Thermal could do proper DFM and optimization proposals for clients. Fast tooling and OTS sample can be achieve.