Are procurement roadblocks holding up your heavy-duty projects? Are you struggling to pick the right electrical cooling plates solutions to buy? Let’s talk about how to solve those problems everything you need to know to make that problem go away right now.

This article outlines the top procurement risks for buying it using a real-world example of a success story. It shows you how XD THERMAL worked with a structural engineer to eliminate these risks and make heavy-duty equipment perform better.

Unclear technical specs is a risk you have to address at the very beginning. Especially when dealing with the high-performance needs of heavy-duty equipment. I was approached by a structural engineer who works on this heavy-duty equipment. This particular engineer came to us with some preliminary specs regarding the cooling plates and enclosures he needed for thermal protection of his applications. He also had some preliminary ideas about the thermal exchange he needed from our plates.

While the customer had some design parameters, they were not so concrete about exactly what they needed as far as thermal performance. By having some conversations with them, we were able to make sure there wasn’t going to be some huge disconnect between what they thought they were going to get and what we delivered to them.

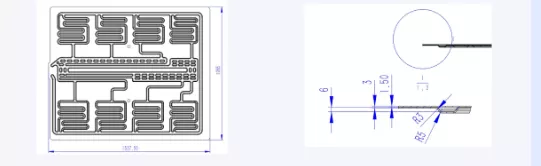

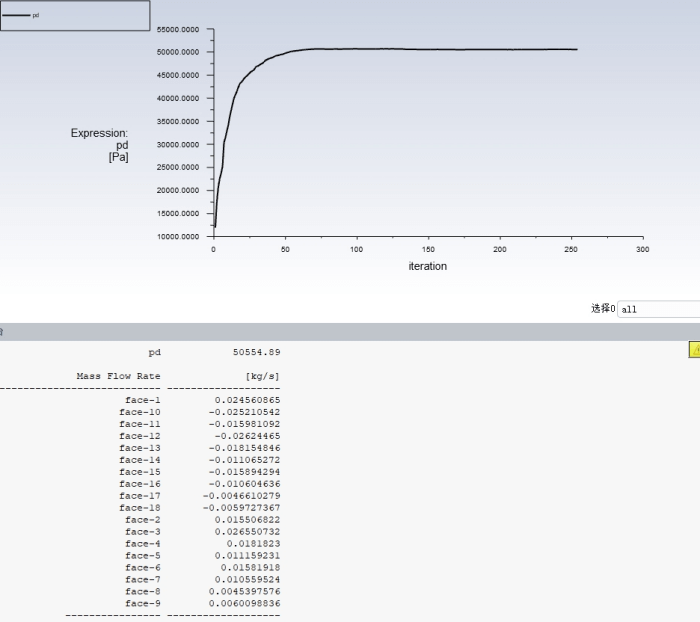

Design space limitations and manufacturing constraints are risks number two in heavy-duty applications. Based on the work we’d done in phase one, we did some simulations based on their design to make sure our cooling plates would exchange enough heat in the room they had available for the parts.

Through a combination of tweaking the design of the flow channels for the coolant and altering the dimensions, we were able to deliver an improved performance from the same size piece. We also ensured that they would be able to make the plates in their own fab shop.

Another challenge Procurement professionals typically run into is when the technical adjustments you need to make end up having an impact on the cost change. We provided a detailed and itemized quote that showed exactly what they were getting with the updated design and why the costs had changed.

With over ten years of overseas manufacturing experience, we were able to see ahead into the future and what challenges they might have with raw material handling, mold management, and coordinating all these shops on the production line. We made sure we anticipated everything that could go wrong and put manpower in place in advance so they would make things on time.

Once again, due to the tough operating conditions of these things in the heavy-duty application, they were especially worried about getting a pile of junk. We recommended that they do a full comprehensive Design Verification (DV) and Process Verification (PV) test to

make sure our part was going to work the way we said it was. To tighten up this process and lower the cost for the customer, we did full inspections during the sample phase. After that, we switched to sampling inspections once we were in mass production.

In the logistics segment, booking and shipping are the main risk points. Initially, the customer wanted to use their own logistics provider, but the logistics department was overwhelmed during a peak booking period. This resulted in delays with both container bookings and shipping schedules.

To ensure the timely progress of the project, XD THERMAL took swift action by coordinating with its internal logistics team. Through proactive management, we successfully assisted in the shipping process and ensured the goods were delivered on time, preventing potential project delays.

After-sales support plays a crucial role in the success of any procurement process, especially in heavy-duty applications where cooling plate performance is critical to operational efficiency. Following the delivery, XD THERMAL maintained regular contact with the client to ensure that the cooling plates were performing as expected.

We also provided ongoing technical support, answering any questions the client had and addressing potential concerns before they became critical. The client appreciated our proactive approach, which helped build long-term trust and confidence in our services.

An ideal supplier offers end-to-end services—from design and prototyping to mass production. Facilities like self-owned extrusion lines ensure scalability and flexibility. Experience with complex, customized projects and efficient communication are crucial for timely, successful completion. Suppliers like XD THERMAL also help address procurement risks by providing clear technical specifications, robust supply chains, and stringent quality control during manufacturing.

This case study highlights the importance of effective procurement in heavy-duty applications, from clarifying initial requirements to ensuring quality control and timely delivery. By identifying risks early and addressing them proactively, XD THERMAL ensured that the project was completed successfully, improving the client’s overall operational efficiency.

For procurement professionals working with heavy-duty equipment, this success story emphasizes the importance of clear communication, technical coordination, and risk management throughout the procurement process.

Looking forward, XD THERMAL continues to partner with more businesses in the heavy-duty industry, contributing to the growth and success of complex thermal management projects.

Procurement risks include unclear technical specifications, supply chain disruptions, manufacturing constraints, cost adjustments due to design changes, and logistics delays. These risks can affect product quality, increase costs, and delay project timelines. Proactively addressing these risks ensures smoother project execution and higher-quality outcomes.

XD THERMAL implements comprehensive quality assurance procedures, including Design Verification (DV) and Process Verification (PV) tests. During the sample stage, we perform full inspections to ensure the product meets all specifications. In the mass production stage, we conduct sampling inspections to maintain efficiency while ensuring high-quality standards.

With over ten years of experience in foreign trade, XD THERMAL anticipates supply chain disruptions and logistics challenges. We make arrangements in advance for raw material handling, mold management, and factory production line coordination.

XD THERMAL selects reliable logistics providers and maintains real-time communication throughout the shipping process. If a client’s preferred logistics provider is unavailable or delayed, we actively coordinate internally to arrange alternative shipping options

DV and PV testing are crucial for validating the performance and reliability of a product under real-world conditions. Design Verification ensures the product meets its design specifications, while Process Verification confirms that the manufacturing process consistently produces high-quality products. This comprehensive testing helps mitigate risks during both the sample and mass production stages.

I've worked in battery thermal management for over 5 years, handling lots of international projects. If you're curious about battery liquid cooling products or services, feel free to ask me any questions!