Stamped liquid cold plates are vital components in industries such as electronics, automotive, and renewable energy. They serve as an effective thermal management solution, dissipating heat efficiently in applications where high-performance cooling is essential. Among the materials used in their construction, aluminum stands out as a preferred choice due to its exceptional thermal conductivity, light weight, and versatile processing characteristics.

The primary function of a liquid cold plate is to transfer heat from critical components, such as power electronics or battery modules, to a liquid coolant circulating through internal channels. To achieve this, the material of the cold plate must offer a combination of high thermal conductivity, light weight, and structural strength.

Aluminum fulfills these criteria better than most alternatives, such as copper or composite materials. Specifically:

These characteristics make aluminum the most commonly used material in liquid cold plate manufacturing.

Different applications require specific aluminum grades that balance thermal performance, mechanical strength, and corrosion resistance. Below are the most widely used aluminum grades in the production of stamped liquid cold plates:

– Features: A pure aluminum sheet with a high aluminum content of 99.5% or more. It offers outstanding thermal conductivity and excellent corrosion resistance but relatively low mechanical strength.

– Applications: Suitable for high-thermal-demand environments, such as electronic cooling systems or heat exchangers, where mechanical loads are minimal.

– Features: Slightly purer than 1050, with an aluminum content of 99.6%. It shares similar properties, including excellent corrosion resistance and thermal conductivity, with marginally better strength.

– Applications: Commonly used in electric vehicle (EV) battery cooling plates, where weight and thermal efficiency are critical factors.

– Features: An aluminum-manganese alloy that enhances corrosion resistance and strength compared to pure aluminum grades. It retains good thermal conductivity, making it versatile for liquid cold plate applications.

– Applications: Frequently used in electric vehicle (EV) battery cooling plates, industrial cooling systems, renewable energy equipment, and other applications requiring higher durability.

– Features: An aluminum-magnesium alloy known for its superior strength, corrosion resistance, and excellent formability. It offers a good compromise between mechanical properties and thermal efficiency.

– Applications: Preferred for high-performance automotive and aerospace cooling systems, where both strength and weight reduction are essential.

– Features: A heat-treated aluminum-magnesium-silicon alloy that provides excellent strength, corrosion resistance, and weldability. However, its thermal conductivity is slightly lower than pure aluminum.

– Applications: Best suited for applications that require high structural integrity, such as in heavy-duty equipment or custom liquid cooling solutions.

Producing aluminum sheets for liquid cold plates involves multiple steps, each tailored to achieve the required mechanical, thermal, and surface characteristics. Below is a detailed breakdown of the process:

The process begins with the smelting of aluminum ingots, where pure aluminum is combined with specific alloying elements, such as manganese, magnesium, or silicon. The mixture is melted and refined to eliminate impurities and ensure consistent material properties.

The molten alloy is cast into ingots or slabs through processes such as direct-chill (DC) casting. These ingots are the raw material for subsequent rolling processes.

The aluminum ingots are preheated and passed through a series of rolling mills to produce sheets of intermediate thickness. This process enhances the material’s ductility and prepares it for further processing.

After hot rolling, the sheets are annealed and further processed at room temperature through cold rolling. This step reduces the sheet thickness to meet specific requirements, such as the precise dimensions needed for liquid cold plates.

– Cleaning and Polishing: Removes surface oxides and impurities.

– Anodizing or Coating: Increases corrosion resistance and improves surface finish. Some applications may require additional surface coatings, such as fluoropolymer or epoxy layers, for enhanced durability.

The processed sheets are cut to the desired sizes and carefully packaged to prevent damage during transportation.

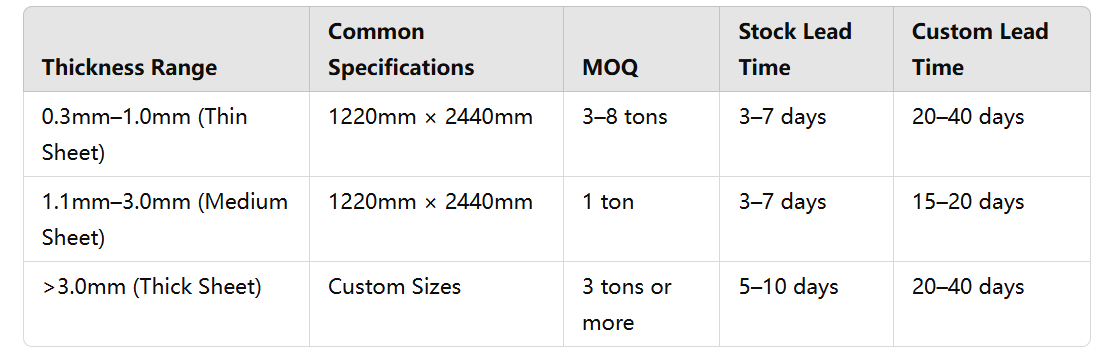

The MOQ for aluminum sheets depends on the supplier, grade, and customization requirements:

Common grades like 1050, 1060, and 3003 typically have a lower MOQ, ranging from 1 to 2 tons. These grades are widely used and often available in stock, allowing smaller order sizes.

For specialty alloys such as 5052 or 6061, or sheets requiring unique thicknesses or surface treatments, the MOQ can be significantly higher, often 5 to 10 tons or more.

Thin Sheets (0.3mm–1.0mm): Thin sheets are more challenging to process due to higher scrap rates and lower production yields. Typically, the MOQ for thin sheets ranges from 3–8 tons.

Medium-Thickness Sheets (1.1mm–3.0mm): These are the most commonly used thicknesses for AL3003 aluminum sheets, with mature production processes and sufficient inventory. The MOQ is generally lower, around 1 ton.

Thick Sheets (>3.0mm): Thick sheets are often used for customized applications, and their MOQ is higher, typically 3 tons or more.

Standard Sizes: Common sizes such as 1220mm × 2440mm or 1000mm × 2000mm are usually readily available in stock, allowing for lower MOQs.

Custom Sizes or Shapes: Sheets requiring custom cutting or sizing typically have a higher MOQ, usually 2 tons or more.

Understanding the MOQ is critical for manufacturers to balance inventory costs and ensure timely project execution.

Lead time varies based on several factors, including stock availability, order complexity, and supplier capacity:

If the required AL3003 aluminum sheet is available in stock (common thicknesses and sizes), the lead time is typically 3-7 business days.

For non-standard grades, specific dimensions, or additional processing (e.g., anodizing, special coatings), lead times can extend to 20–40 days, depending on production schedules.

Market fluctuations, such as increased demand in the EV sector, can impact both availability and lead times. Manufacturers should plan accordingly during peak demand periods.

Selecting the appropriate aluminum sheet requires careful consideration of several factors:

Applications with high thermal loads prioritize materials with excellent thermal conductivity, such as 1050 or 1060 aluminum.

For environments with mechanical stresses, alloys like 5052 and 6061 provide better durability.

Applications exposed to moisture or chemicals may benefit from anodized or coated aluminum sheets.

Lightweight solutions like 3003 aluminum strike a balance between cost and performance.

Aluminum sheets are indispensable in the production of stamped liquid cold plates, with commonly used grades such as 1050, 1060, 3003, 5052, and 6061 offering diverse performance benefits. The production process, from smelting to surface treatment, ensures the sheets meet stringent quality standards for thermal conductivity, strength, and corrosion resistance. MOQs and lead times depend on the grade and order specifications, making it essential for manufacturers to plan carefully to meet project timelines and budgets.

By understanding the properties of different aluminum grades and aligning procurement strategies with production requirements, companies can enhance the performance of their liquid cooling solutions while maintaining competitive costs and lead times. This comprehensive approach ensures success in an increasingly demanding and fast-evolving market.